Our company offers the best Russian technology and equipment for production of building materials, products and structures, as well as the generation of electrical energy.

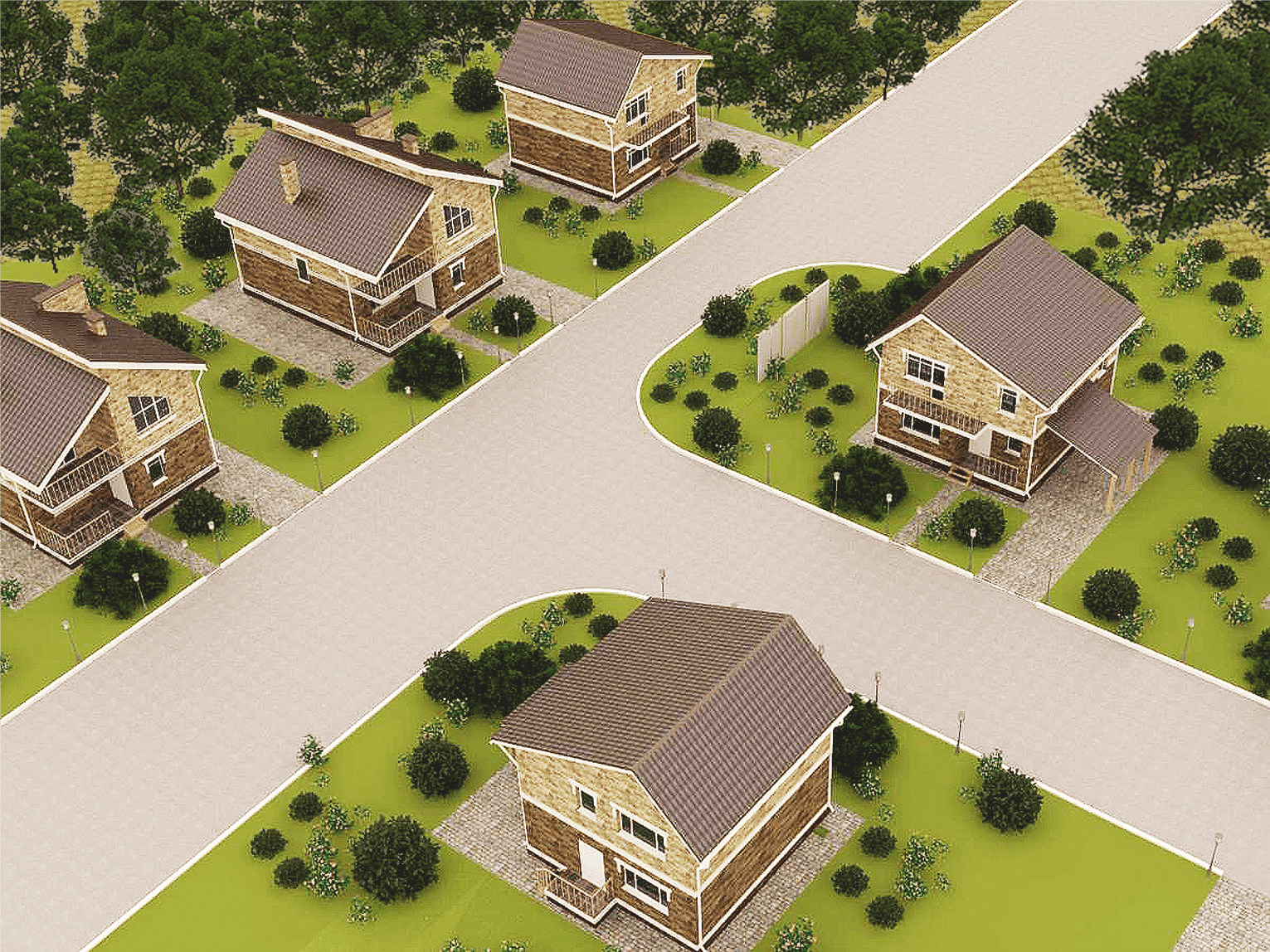

Equipment for the production of building materials can work both separately and as part of house-building plant.

The walls and partitions, ceilings, fences, roofs and windows, drainage systems and construction elements – all that is needed for the construction of low-rise and high-rise buildings of different purposes.

The plant can produce materials and products for buildings ranging from 80 to 900 thousand m2 of ready housing per year.

To supply the enterprises and settlements with electric energy, we offer a small hydroelectric power and thermal power stations.

For diagnostics of pipeline systems, the design of linearly extended objects, monitoring of the technical condition of the technological facilities of road and rail transport, power transmission lines we offer the technology using video-thermal complex based on helicopter and groundbased complex.

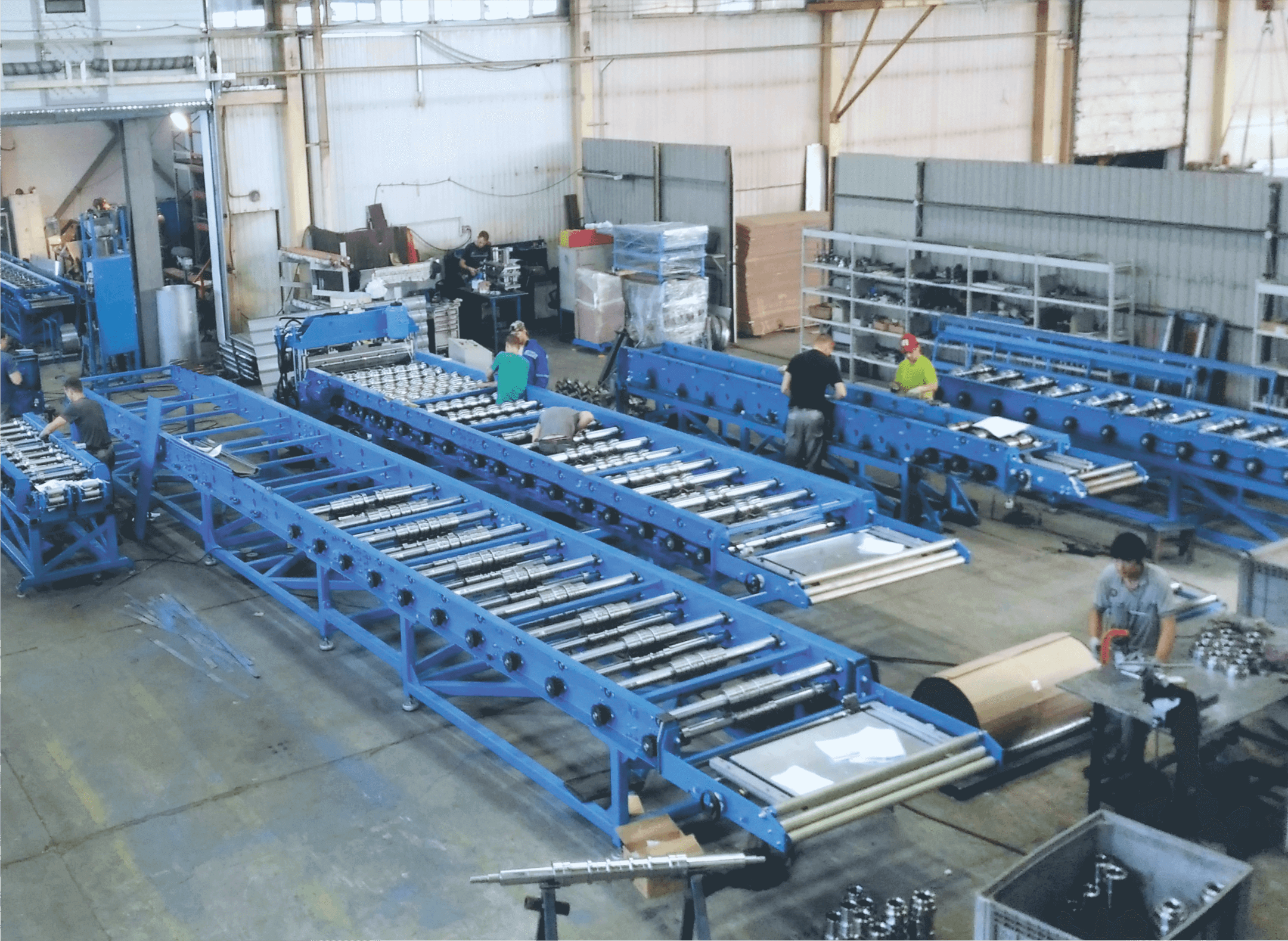

The set of equipment may include a mechanized or automated line for making components and placing them in molds, and a combination thereof.

The plant capacity could reach 18 000 m3 (600 000 units) per year to 180 000 m3 (6 000 000 units) per year. It is equal to 40 000 - 400 000 m2 of ready housing per year.

The plant pays off itself for 5-6 years (including the cost of industrial buildings, infrastructure etc.) or 3-3.5 years without the cost of construction.

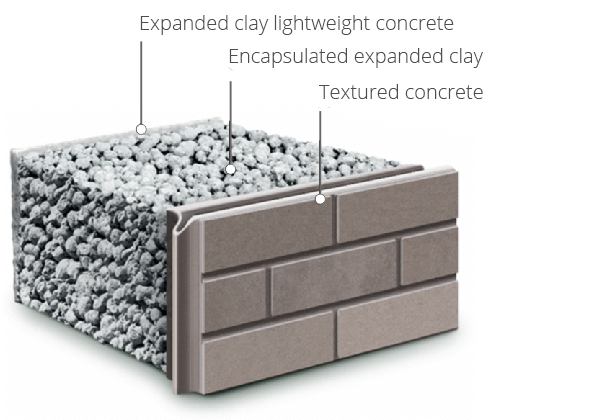

The front of the outer surface of the block has a textured surface that imitates the masonry and/or various kinds of natural stone, relief decorations, etc.

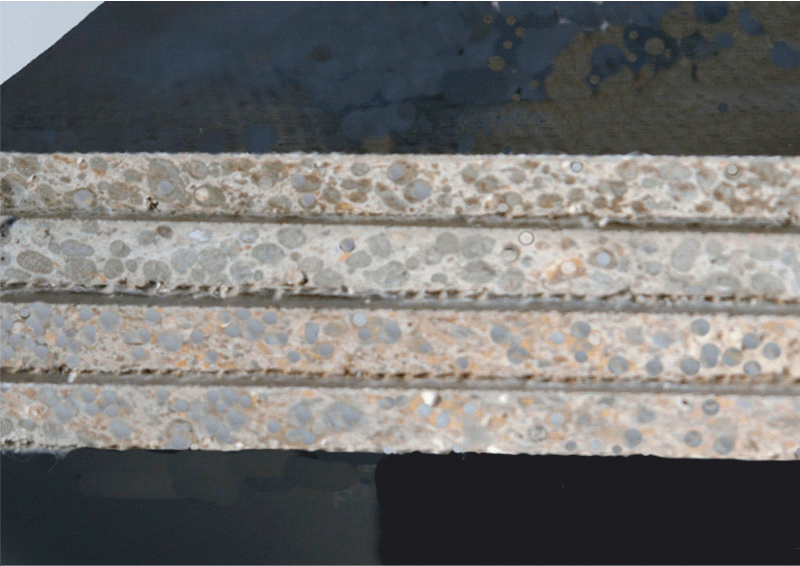

This surface is followed by the base layer of expanded clay encapsulated.

The brick has the low consumption of cement due to the honeycomb structure whose strength is provided by the contacts of shells on the base of high-strength binding agent.

The inner surface of the block has the smooth texture, ready for finishing.

The process of erecting the wall of the blocks is carried out by single-row chain method. Units put on the adhesive foam reach the maximum strength of the wall construction within few hours. It allows you to not limit the performance of the team of masons with technological breaks of usual masonry.

No additional furnish of the exterior part of walls is required upon completion of mason works. The outer wall surface is colored using an airbrush or other conventional means. The inner part of the wall does not require plastering – it is necessary to putty only with subsequent painting or wallpapering.

Due to the special design of blocks the wall composed of them doesn't need not further plastering or tiling. It is just enough to paint from outside and to putty 2 and paint from inside. The walls of the building of 100 m are raised by 4 workers within 4 days. The worker could be taught during 1 day. The material is suitable for self-construction of 1 and 2-storied buildings.

Capital walls of the building made of the blocks are wind-proof, moisture-proof, and do not rot, well retain heat or cold of the building and have an attractive appearance. They provide the excellent protection from street noise and are suitable for securing the hinged furniture and equipment. The service life of these buildings is up to 100 years. Blocks have absolute fire resistance.

The cost of the finished outer wall with the surface of 1 m2, including the cost of masonry work and painting is only US$ 50.

Thus, the "box" of 2-stored house with the living space of 100 m2 erected on the ready basement will cost $ 8000.

For the construction of buildings higher than 2-storied ones we offer precast concrete frame, which allows to erect buildings from 3 to 9 floors, including buildings for seismically dangerous areas.

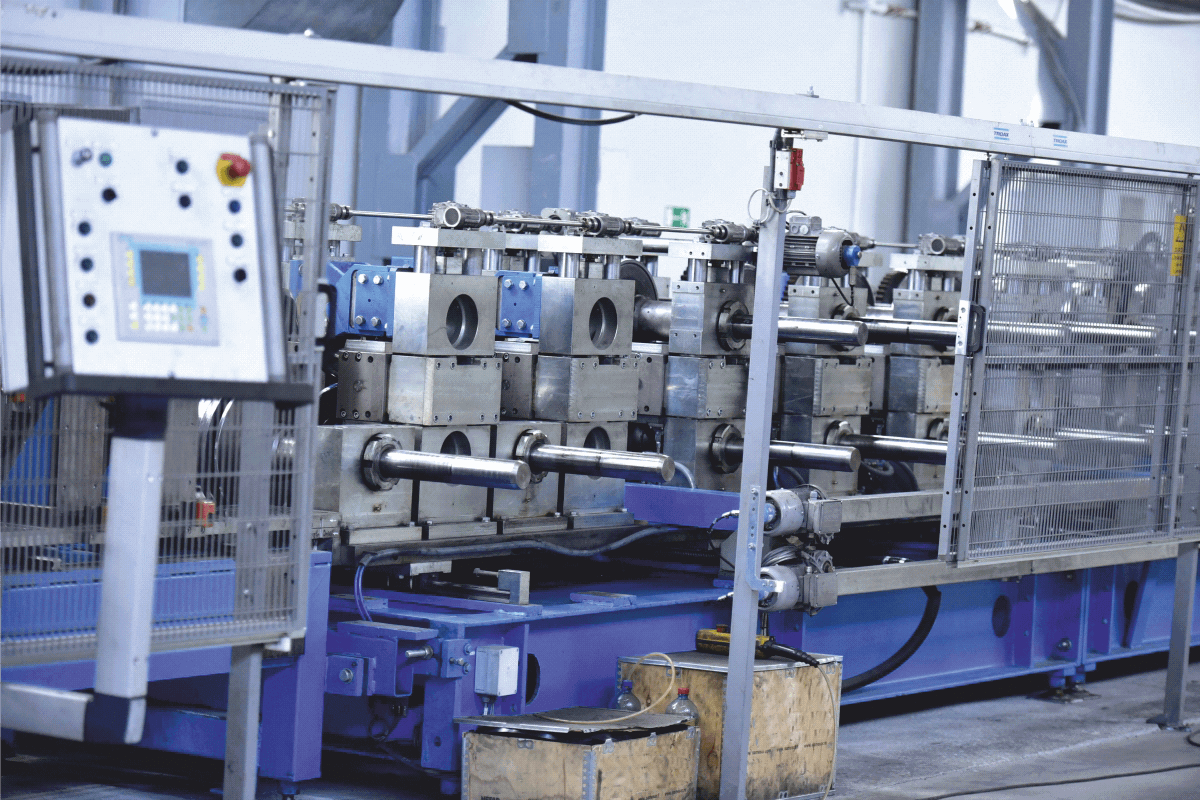

The plant for the production of light steel structures allows producing the full range of products required for the construction of buildings, including structural elements of buildings – columns, beams, rafters, wall sections and floors, metal tiles, gutters and fences.

In combination with other materials for wall construction - blocks, sheet and insulation materials, concrete and reinforced concrete structures, the construction of residential and industrial buildings of every imaginable kind becomes possible.

Any combination of equipment can be implemented as part of housebuilding plant ranging from the minimum number of necessary lines to the maximum possible ones.

The buildings of complex shape could be erected of light steel structures.

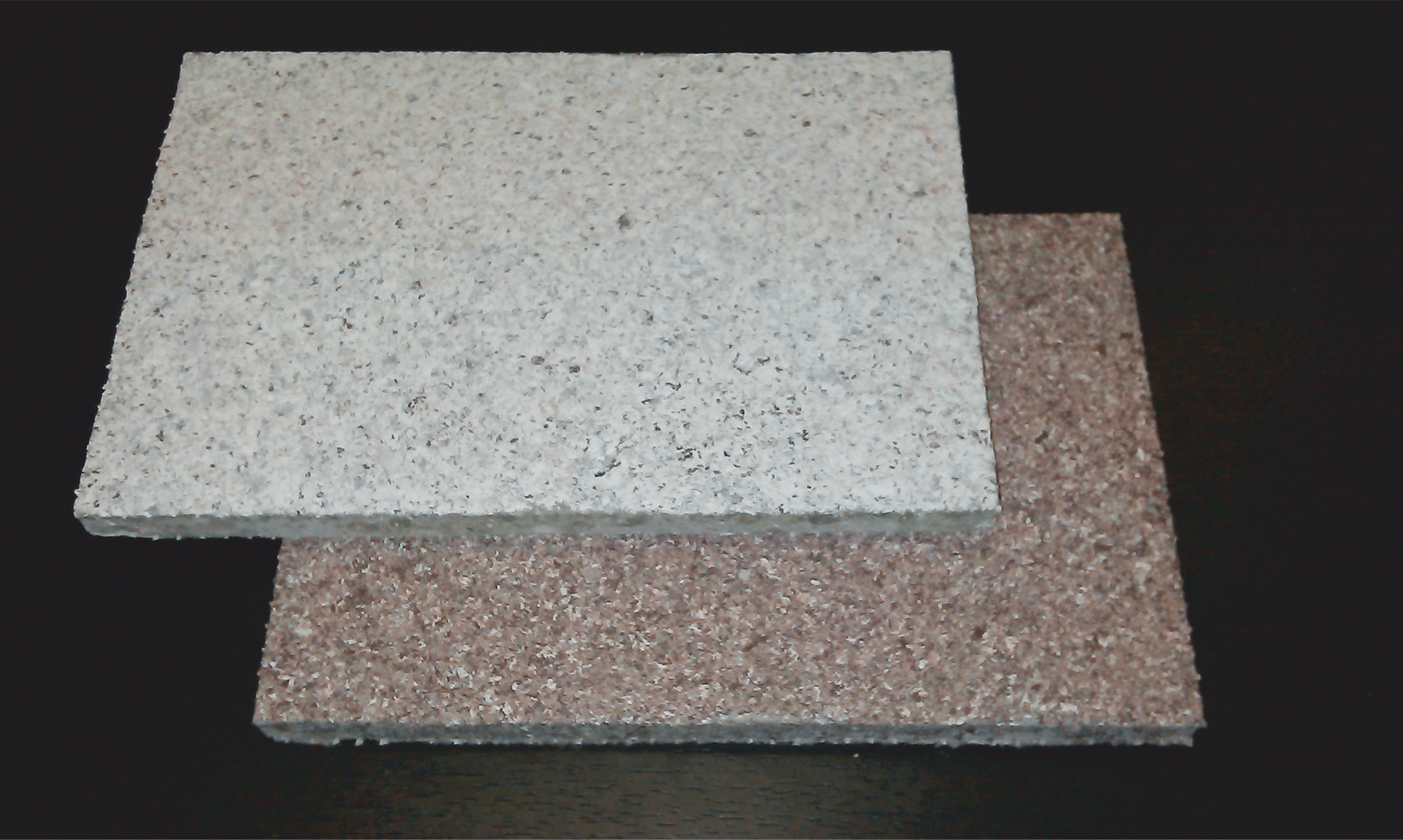

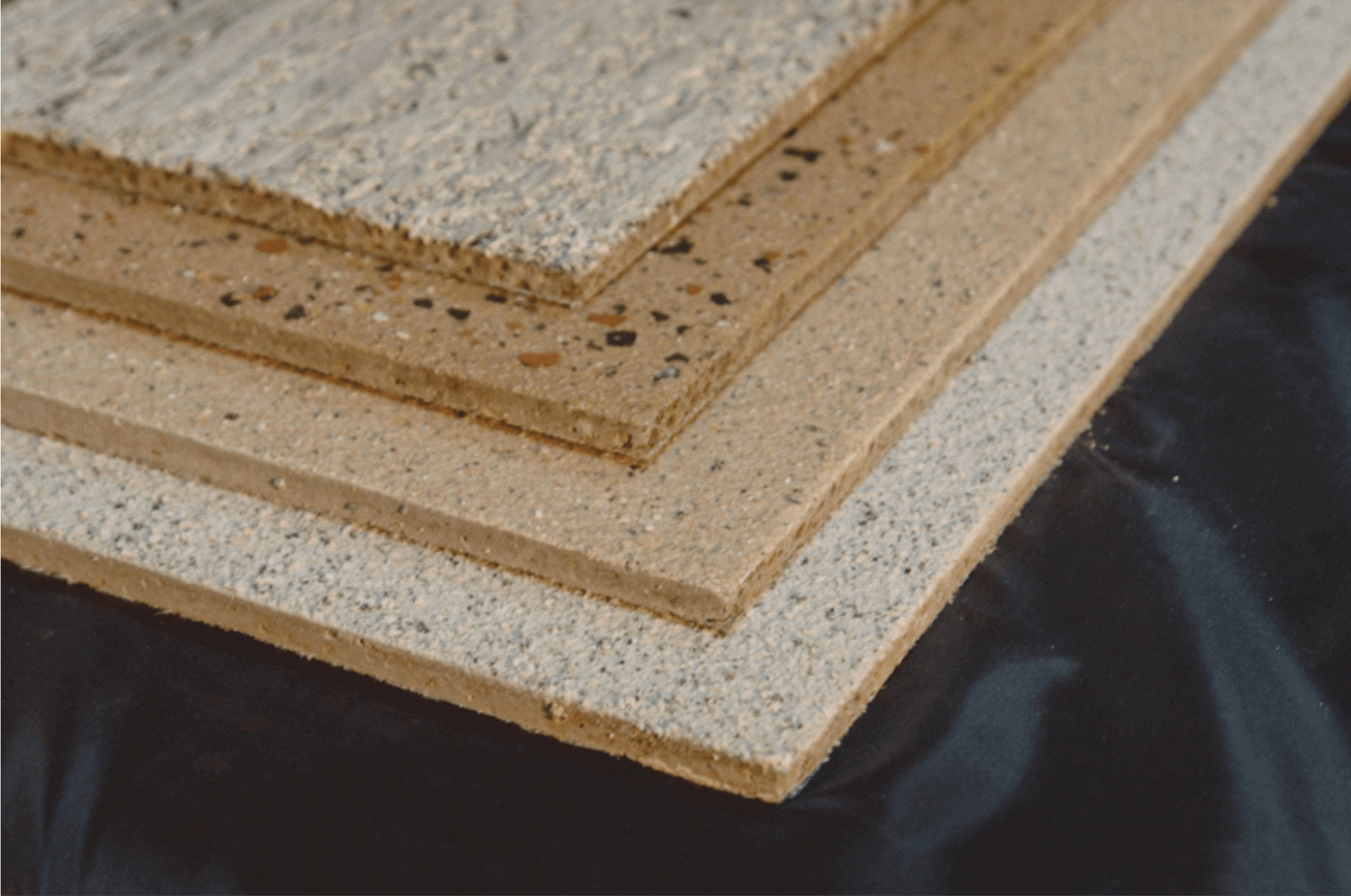

Composite mineral panels comprising a cement binder, sand, reinforcing mesh and expanded clay encapsulated.

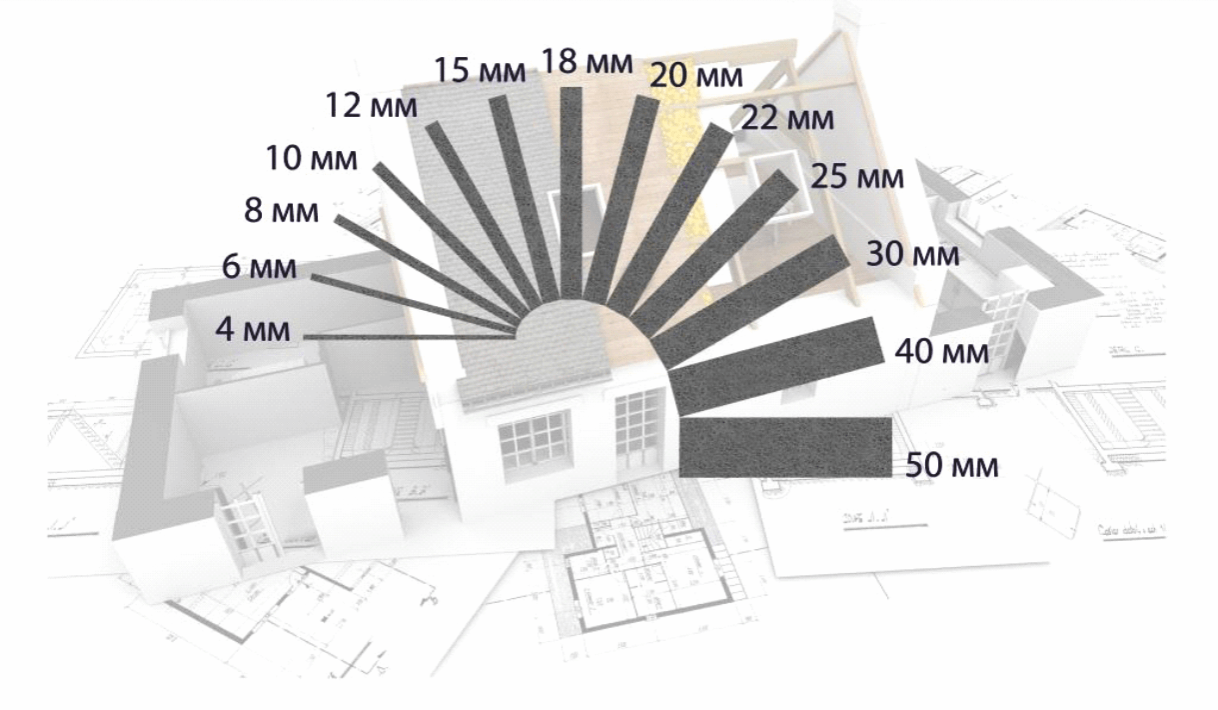

The range of produced noncombustible mineral composite panels "STEKLOTSEM" by thickness

The panels are produced by vibrorolling technology. This technology allows producing panels with variable density and strength in accordance with the height of the section. The whole technological cycle of production is fully automated.

The obverse surface of the panels is glossy without cavities and irregularities. The panels can be painted and laminated. High geometric accuracy of the panels is provided by treating quadrilateral automatic cutter.

Panels are available in range of thermal insulation (soundproof), constructional and thermal insulating and structural materials. They are used in internal and external works both.

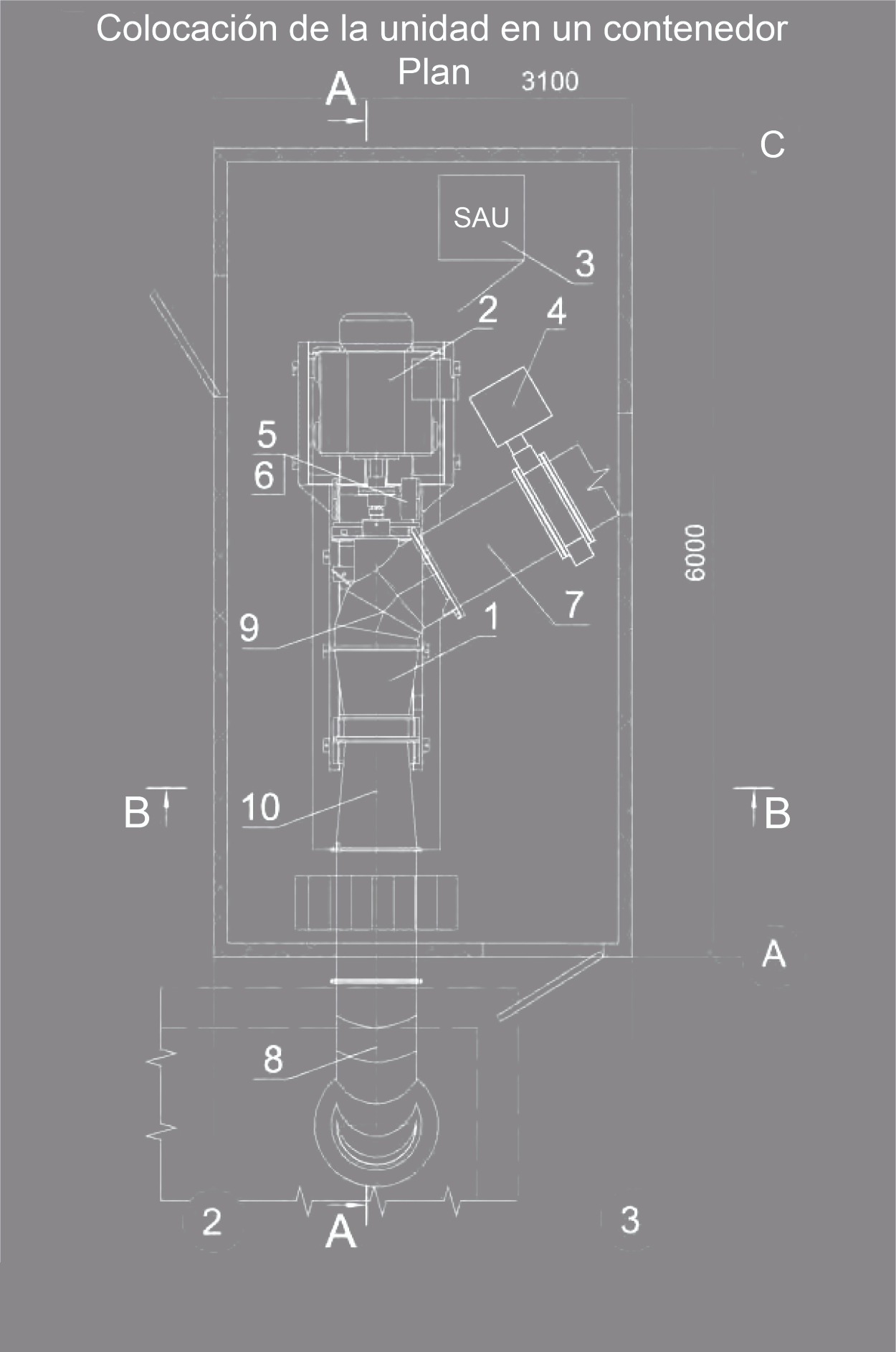

Development, serial production, complete delivery and installation of hydraulic units for small hydro power plants with unit capacity of 5 MW and micro hydroelectric power from 3 to 100 kW. The product range comprises 34 hydroelectric units (pressure from 3 to 450 m).

Up to date in the Russian Federation, as well as in Armenia, Belarus, Georgia, Kazakhstan, Tajikistan and Uzbekistan more than 100 small and micro hydro power plants with total capacity of over 25 MW are installed and put into operation.

More than 50 hydroelectric units were supplied to Sweden, Finland, Japan, South Korea, Panama, France, Brazil, Afghanistan and other countries.

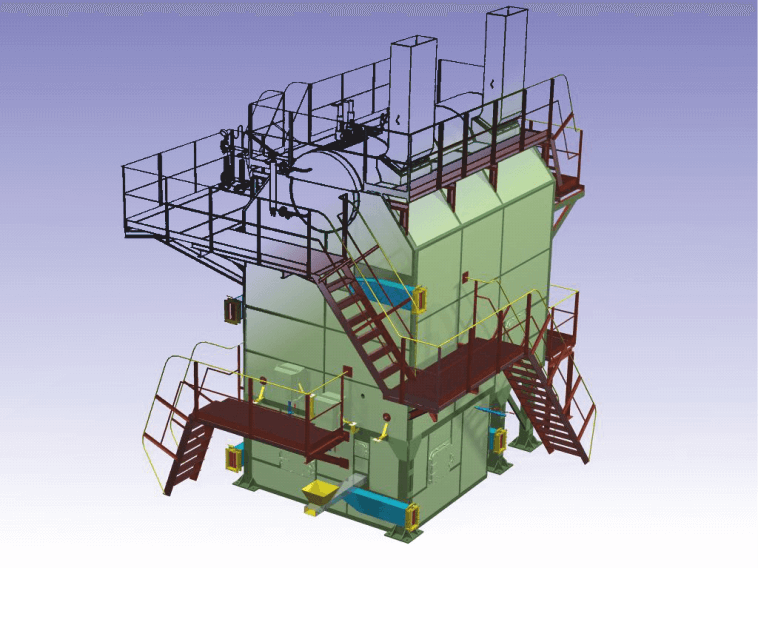

Complex delivery of equipment for mini-TPP (Thermal Power Plants) on renewable fuel (wood chips, husk and other waste) for combined heat and power producing with the capacity ranging from 1 to 4 MWt (within ±5%) with the generator voltage ranging from 0.4 kV till 10 kV.

The produced heat can be used for drying wood, processing of agricultural products, air-conditioning or technological cooling.

The following items could be produced on the spot: